The agricultural sector is the backbone of economies worldwide, and tractors play a pivotal role in enhancing agricultural efficiency. To ensure optimal performance and durability, tractor casting parts manufacturers play a crucial role in providing high-quality components. This article explores the significance of tractor casting parts in optimizing tractor functionality, delving into the manufacturing processes, key components, and the role of manufacturers in the agricultural machinery industry.

The Importance of Tractor Casting Parts

Enhanced Durability

Tractors are subjected to rigorous conditions in the field, and the durability of their components is paramount. Tractor casting parts, made from robust materials such as iron and steel, contribute to the overall strength and longevity of the machinery.

Precision Engineering

Casting parts are intricately designed and manufactured using precision engineering techniques. It ensures that each component fits seamlessly into the tractor's structure, minimizing wear and tear while maximizing efficiency.

Critical Role in Tractor Performance

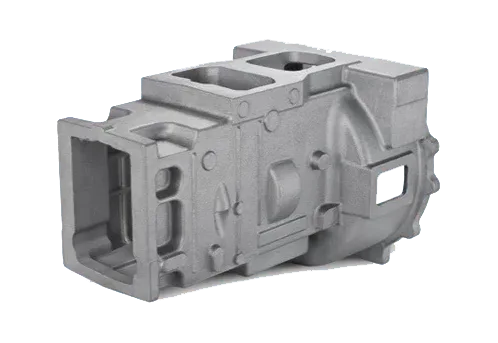

Various critical components of a tractor, including engine blocks, transmission housings, and axle casings, are crafted using casting processes. The performance of these components directly influences the overall functionality of the tractor in the field.

Key Tractor Casting Parts and Their Functions

Transmission Housings

The transmission mechanism plays a crucial role in channeling power from the engine to the wheels, ensuring a seamless transfer of energy for optimal vehicle performance. Casting parts, such as transmission housings, are crucial for maintaining the alignment and integrity of the transmission components, enabling smooth and reliable power transmission.

Engine Blocks

The engine block is the core component of a tractor's power unit. Tractor casting parts manufacturer employs casting processes to create durable and heat-resistant engine blocks. It ensures efficient combustion and power generation, contributing to the tractor's overall performance.

Axle Casings

Axle casings, often subjected to substantial stress in the field, are crafted using casting techniques for added strength. These casings protect the tractor's axles and differential components, ensuring stability and reliability during heavy-duty operations.

Wheel Hubs and Brackets

Casting parts also contribute to the construction of wheel hubs and brackets, providing the necessary structural support for the tractor's wheels. These components are designed to withstand the load and pressure exerted during agricultural tasks.

Hydraulic Components

Many modern tractors feature hydraulic systems for various functions, including lifting and lowering implements. Casting parts are utilized in the production of hydraulic components such as pump housings, cylinders, and valves, ensuring the hydraulic system's efficiency and longevity.

Manufacturing Processes for Tractor Casting Parts

Sand Casting

Sand casting is a widely employed method for manufacturing tractor casting parts. This process entails the formation of a mold through the utilization of sand, followed by the precision pouring of molten metal into the resulting mold cavity. The process is versatile and cost-effective, making it suitable for producing large and complex components.

Investment Casting

Investment casting, also known as precision casting, is utilized for intricate and complex tractor parts. This process involves creating a wax pattern, coating it with a ceramic shell, and then pouring molten metal into the mold. It is particularly suitable for components requiring high precision.

Die Casting

In the die casting process, molten metal is injected into a mold cavity with precision under elevated pressure. This process is commonly used for manufacturing tractor casting parts with intricate shapes and fine details. It ensures a high level of dimensional accuracy and surface finish.

Quality Assurance and Compliance

Material Selection

Tractor casting parts manufacturers prioritize the selection of high-quality materials, such as ductile iron, gray iron, and alloy steels. The choice of materials is crucial for ensuring the desired strength, durability, and performance of the components.

Quality Control Measures

Vigorous quality assurance protocols are seamlessly integrated at every stage of the manufacturing journey. It includes inspection of raw materials, monitoring of casting processes, and thorough testing of finished components to ensure they meet industry standards and specifications.

Compliance with Standards

Manufacturers adhere to national and international standards to ensure that their tractor casting parts comply with safety and performance regulations. Compliance with standards is essential for building trust with tractor manufacturers and end-users alike.

Role of Tractor Casting Parts Manufacturers

Innovation in Design

Manufacturers continuously invest in research and development to innovate tractor casting part designs. It involves optimizing shapes, materials, and manufacturing processes to enhance performance, reduce weight, and improve fuel efficiency.

Customization for Clients

Recognizing the diverse needs of tractor manufacturers, casting parts manufacturers offer customization services. It allows clients to request specific designs, materials, or finishes tailored to their unique tractor models and applications.

Supply Chain Management

Efficient supply chain management is crucial for meeting the demands of the agricultural machinery industry. Tractor casting parts manufacturers work closely with suppliers to ensure a steady and reliable supply of raw materials, minimizing production delays.

Also Read: A Closer Look at Automobile Casting Components

Challenges and Future Outlook

Environmental Considerations

Tractor casting parts manufacturing processes, particularly traditional methods, may have environmental implications. Manufacturers are exploring sustainable practices, such as the use of recycled materials and energy-efficient processes, to mitigate these concerns.

Global Economic Trends

The tractor industry is influenced by global economic trends, and manufacturers must navigate fluctuations in demand, trade policies, and raw material prices. Adaptable strategies and robust business models are essential for long-term success.

Technological Integration

The integration of advanced technologies, such as digital simulations and additive manufacturing, presents both opportunities and challenges for tractor casting parts manufacturers. Embracing these technologies can enhance efficiency but requires investments in training and infrastructure.

Wrapping Up

As agriculture continues to evolve with technological advancements, the role of tractor casting parts manufacturers remains pivotal in supporting the industry. Their commitment to precision engineering, quality assurance, and innovation contributes to the overall efficiency and durability of the tractors, ensuring they meet the demands of modern farming. With a focus on sustainability and adapting to changing global landscapes, these manufacturers are integral to the ongoing optimization of tractor functionality in the agricultural sector.